Practical Solutions. Proven Results.

Specialized HRSG and Power Plant Consulting Services That Deliver.

A complete set of on-site and engineering services for your power generation and steam process plants.

With today’s lean staffing models, plant personnel are often stretched thin and managing multiple priorities with limited time. Sieben Power Consulting (SPC) can supplement your team by deploying experienced engineers to be on site and ready to focus on critical projects and deliver timely, effective solutions. We take pride in our engineering depth and enjoy helping clients overcome persistent operational challenges. Our solutions are objective, data-driven, and calculation-based. Whether you’re dealing with cycling drain pots, failed hanger restraints, attemperator overspray, undrained condensate, blowdown failures, or other thermal performance concerns, we’re here to help you resolve them efficiently and confidently.

HRSG Inspections & Performance Assessments

Offline Inspections

We perform comprehensive walkdowns including internal inspections (crawl spaces, boiler drums, gas path) and external casing assessments. You'll receive an on-site punch list of priority issues followed by a detailed final report with photos and recommended actions. Optional borescope of the water side from the steam drums and/or drone inspections of duct burners, catalyst and AIG, tube surfaces, and vent silencers reduce access costs and improve safety.

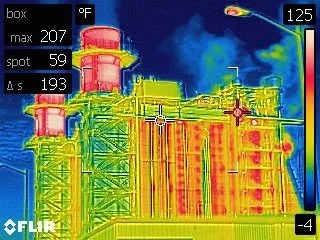

Online Thermal Imaging

Using infrared imaging, we detect and document casing hot spots with digital/thermal photos and real-time repair advice. Final reports help you target future maintenance and outage planning effectively.

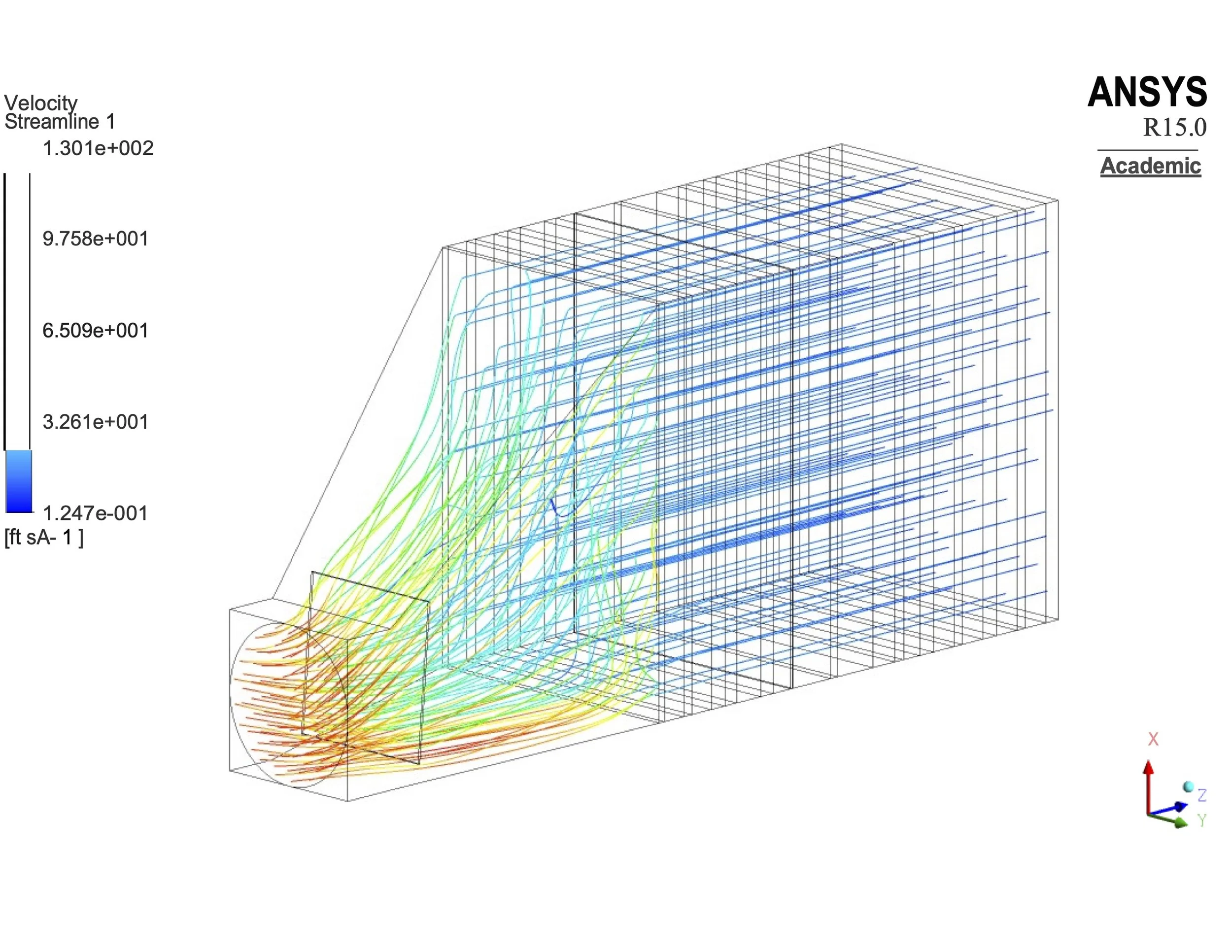

HRSG Thermal & Operational Evaluations

Low Load Operation Studies

We assess how low load conditions affect HRSG integrity. Our analysis compares real-time operating data against original design specs, identifies circulation and thermal risks, and recommends operational or equipment modifications.

Cycling Studies

Our team evaluates your startup/shutdown procedures to ensure they’re minimizing damage from cycling and altering operators to damage causing mechanisms. We'll review documentation, observe processes, and offer economic improvements to reduce thermal fatigue and wear.

Performance Evaluations (Including Combustion Turbine Upgrade Impacts!)

We use thermal modeling to evaluate HRSG performance under current or upgraded operating conditions (e.g. AGP, 2x1, 1x1, GTOP). Final reports compare real vs. predicted performance and offer optimization steps.

Root Cause Failure Analysis

Experiencing repeated issues in the same components? We investigate underlying failure mechanisms and recommend cost-effective solutions to eliminate chronic problems.

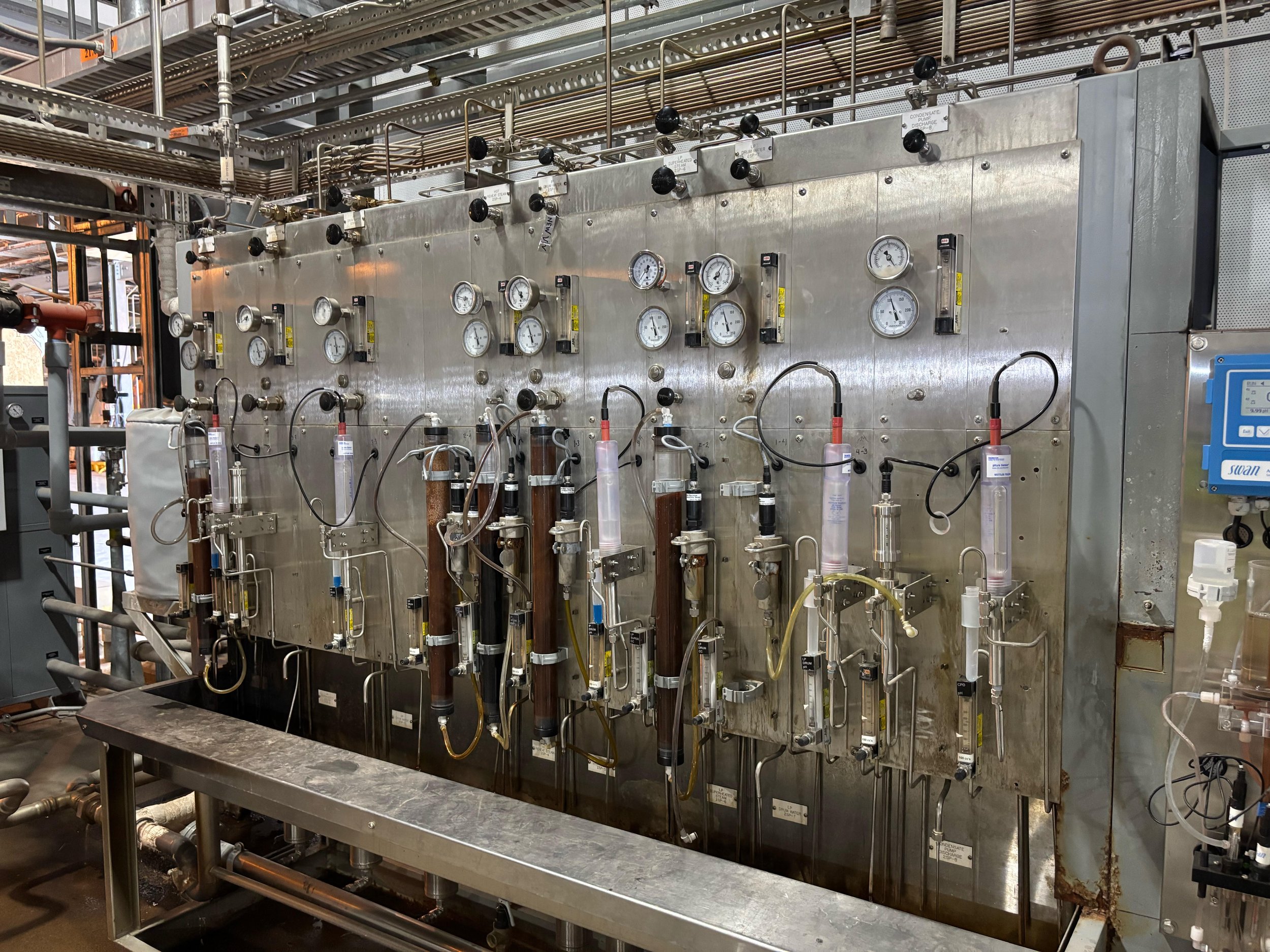

Chemistry & FAC Consulting

Water Chemistry Assessments

We assess your chemical treatment program (AVT, phosphate, FFA), sampling methods, and procedures. Our focus: simplify operations while maintaining chemistry control during cycling.

FAC (Flow-Accelerated Corrosion) Risk Assessments

We combine hydraulic modeling, thermal data, and plant experience to identify high-risk FAC areas. Deliverables include:

Circuit-by-circuit analysis

Prioritized risk matrix

On-site marking for NDE consistency

Chemistry program review and optimization

HRSG Lifecycle Support

Long-Term Maintenance Planning

We develop an Excel-based planning tool tailored to your plant, outlining maintenance tasks, intervals, labor estimates, and cost projections to support annual outage budgeting.

HRSG Specification & Bid Evaluation

Considering a new HRSG? We review vendor specs, compare OEM risks and benefits, and help forecast 10-year O&M costs. We’ll also recommend programs to maintain asset integrity.

Design Upgrades & Replacement Solutions

We assess the impact of upgrades or retrofits on HRSG performance. We offer custom retrofit design solutions and Owner’s Engineer services from planning through installation.

Specialized Inspection & Engineering Services

High Energy Piping (HEP) Programs

We inspect and evaluate HEP systems per ASME B31.1 CPS guidelines, including hot/cold walkdowns, stress analysis, and NDE guidance. Our phased approach prioritizes cost-effective, plant-specific planning and risk mitigation to truly prevent failures in piping.

Borescope Inspections

We access hard-to-reach areas to check for FAC, cracking, or deposits—helping reduce future maintenance costs and prevent downtime.

Owner’s Engineer Support

With plant teams stretched thin, SPC can deploy focused engineering expertise to troubleshoot issues like:

Aftermarket Retrofits

Entire New HRSG, AIG, SCR/CO Catalyst, Valve, or Piping Specifications

Expert Witness Testimony

Steam or Water Side Contract Negotiation and Resolution

Expert Witness Services

SPC provides objective, technically sound expert witness support for legal or arbitration proceedings involving design, installation, or performance issues.

Strategic & Financial Advisory

O&M and Capital Budgeting

We leverage real-world experience managing budgets across 50+ global plants to help clients build reliable financial models and startup cost forecasts.

Plant Acquisition Due Diligence

We review inspection reports, maintenance history, and current asset conditions to support informed acquisition decisions.

Have a challenge that isn’t listed?

We’ve seen it all and solved most of it—just ask!